Business Sammary

Tokyo Color Gravure Co., Ltd. is manufacturer of decorative printed paper widely use in furniture and building industry.

- Production of decorative printed paper, promotion and sales.

- Various kinds of design printing, resin coating, edge band cutting and laminating.

Our Technical Feature

- We have a superior technology to coat thick resin on thin paper without paper curling.

- Thick coating (solid content around 30g/m2 coating at one time is possible)

- Special coating (enamel coating, abrasion resistance coating, humidity control coating)

- Overglazing (recoating urethane resin 10 times on 23g paper would make total approx. 100g/m2)

Production Technology

Our products feature a high quality and wide varirty of designs which have been manufactured on sophisticated resin combination technology. Our manufacturing facility is not in-line from design printing to resin coating but offline. Our coating machines have been installed apart from gravure printing machine, and those highly-functional, big coating machines have enabled us developing lots of unique specialties until now.

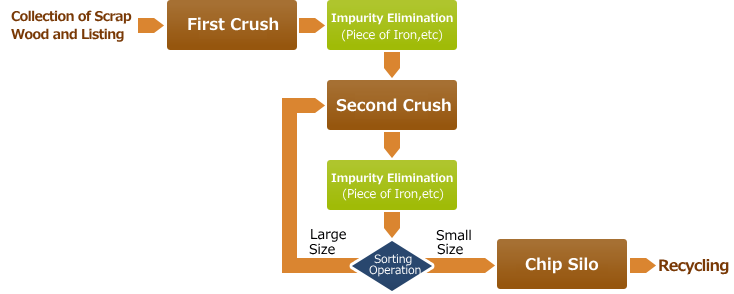

Recycling

Unlike film-based laminate, our product is paper based and is suitable for Thermal Recycling as well as Material Recycling.

Thermal Recycle Generate Electricity Power at Biomass Power Station |

Material Recycle Reuse as Raw Materials for MDF and PB |

|

|---|---|---|

| Paper Overlayed Laminate | Possible | Possible (Paper is made from Wood (Cellulose)) |

| Film Overlaid Laminate | Some Possible | Generally Impossible (Need to separate Surface Film from Base Material) |

Recycle Process Stream

Technical Information on Issue Resolution for Valued Customers

- Work efficiency becomes less efficient because of strong paper curling.

We have a special technology to control paper curling by highly-functional coating machines. - Problem of taping to paper and peeling off.

We can enrich peeling strength by reinforcing base paper with resin or by guarding paper surface with thick coating layer. - High rejection ratio caused by scratching surface at lamination work or press work.

Examination pass rate would raise by our coating technology that would reduce gloss change in scratched area. - Color difference of plywood, particle board, MDF, HDF, and of rough base materials.

Paper surface color may be influenced by color difference of base material by show-through. We can control color change by printing with high hiding power that would hide color difference of base material or by our paper and paper lamination work. - Treatment of special designs upon request.

We are pleased to serve designs with synchronized or random deep embossing or with gloss mat embossing. Those designs are re-creating real wood texture produced through special processes. - Other qualities of our printed decorative paper.

We are always ready to meet our customer's request to finish product with special quality, such as thinner resistance, abrasion resistance, oil resistance, resistance to staining, water resistance, chemical resistance, antibacterial activity, etc.